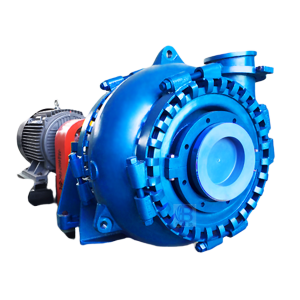

Ipompo ye-TSP/TSPR ethe nkqo eludaka

Ipompo ye-TSP/TSPR ethe nkqo eludakayenzelwe izicelo ezifuna ukuthembeka okukhulu kunye nokuqina kuneempompo zenkqubo eziqhelekileyo ezinokunikezela.I-elastomer efakwe ngokupheleleyo okanye intsimbi enzima ifakwe.Akukho zibheringi ezingaphantsi kwamanzi okanye ukupakisha.Umthamo ophezulu wokufunxa uyilo oluphindwe kabini.Ubude obucwilisiweyo obulungiselelweyo kunye ne-agitator yokufunxa ekhoyo.I-TSP/TSPR impompo yesumpu ethe nkqo ifanelene ngokufanelekileyo nokuphatha ulwelo olurhabaxa kunye nolwelo oludlekayo kunye nolwelo oluntywiliselwa emanzini okanye emingxunyeni.

Iimpawu zoyilo

√ Ukungagugi kancinci, ukubola kancinci

Amacandelo amanzi afumaneka kuluhlu olubanzi lwealloyi kunye ne-elastomers, apho i-Weir Minerals ikhetha eyona ndibaniselwano yemathiriyeli ukuxhathisa ukunxitywa phantse kuso nasiphi na isicelo semizi-mveliso, kuquka ezo zifuna zombini ukurhawuka kunye nokuxhathisa umhlwa kwaye apho amasuntswana amakhulu okanye ukuxinana okuphezulu kwe-slurries. kuhlangatyezwana nazo.

• I-abrasion resistant A05 Ultrachrome® alloy.

• I-alloy ye-A49 Hyperchrome® enganyangekiyo kwi-abrasion/corrosion.

• Iintsimbi ezikwaziyo ukumelana nokubola.

• Ielastomer zendalo kunye nezokwenziwa.

√ Akukho ntsilelo yokuthwala ingaphantsi kwamanzi

I-shaft ye-cantilever eyomeleleyo inqanda imfuno yeebheringi ezingaphantsi kwamanzi - ezihlala zingumthombo wokungaphumeleli kokuthwala kwangaphambi kwexesha.

• Iibheringi zerola enzima, ngaphezu kweplate yokunyusela.

• Akukho zibheringi ezingaphantsi kwamanzi.

• ILabyrinth/flinger ethwele ukhuseleko.

• Eqinile, ishafti enkulu edayamitha.

√ Akukho zingxaki zokutywinwa kweshaft

Uyilo oluthe nkqo lwe-cantilever alufuni ukutywinwa kwe-shaft.

√ Akukho mveliso ifunekayo

Uyilo lwe-inlet ephezulu kunye nesezantsi ifaneleke ngokufanelekileyo kwiimeko "ze-snore".

√ Umngcipheko omncinci wokuthintela

I-inlets ekhuselweyo kunye neepaseji ezinkulu ze-impeller zinciphisa umngcipheko wokuvala.

√ Azikho iindleko zamanzi ancedisayo

Uyilo oluthe nkqo lwe-cantilever olungenawo amadlala okanye iibheringi ezingaphantsi kwamanzi luthintela imfuno yedlala elibiza kakhulu okanye ukugungxulwa kwamanzi.

TSP/TSPRImpompo ethe nkqo eLudakaIiparamitha zoMsebenzi

| Umzekelo | Amandla okudibanisa P (kw) | Umthamo Q (m3/h) | Intloko H (m) | Isantya n (r/min) | Eff.η (%) | Impeller dia. (mm) | Max.amasuntswana (mm) | Ubunzima (ikg) |

| I-40PV-TSP(R) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-TSP(R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100RV-TSP(R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-TSP(R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200SV-TSP(R) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250TV-TSP(R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-TSP(R) | 22–200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

TSP/TSPRImpompo ethe nkqo eLudakas Usetyenziso

Iimpompo ze-TSP / TSPR ze-slurry ze-verrical zifumaneka kuluhlu olubanzi lweesayizi ezidumileyo ukuze zihambelane nezicelo ezininzi zokupompa.Iimpompo ze-TSP/TSPR sump zingqina ukuthembeka kwazo kunye nokusebenza kakuhle kwihlabathi jikelele: ukusetyenzwa kweeminerali, ukulungiswa kwamalahle, ukusetyenzwa kweekhemikhali, ukuphathwa kwamanzi amdaka, isanti kunye negrabile kwaye phantse yonke itanki, umgodi okanye umngxuma-kwimeko yokuphatha uludaka lomhlaba.Uyilo lwempompo ye-TSP/TSPR kunye nokuba yintsimbi enzima (TSP) okanye i-elastomer egqunyiweyo (TSPR) amacandelo yenza ukuba ilungele ukubola kunye / okanye i-slurries eyonakalisayo, ubungakanani besuntswana elikhulu, i-slurries ephezulu yoxinaniso, umsebenzi oqhubekayo okanye "wokurhona", imisebenzi enzima efuna i-cantilever. iishafu.

• Iimpompo ze-TSP ezithe nkqo zodaka kunye neendawo ezisetyenziswayo zitshintsha-tshintsha kuphela iimpompo zodaka oluthe nkqo ze-Warman® SP kunye noomatshini.

TH Cantilevered, Horizontal, Centrifugal Slurry Imathiriyeli yeMpompo:

| Ikhowudi yezinto eziphathekayo | Inkcazo yezinto | Amalungu eSicelo |

| A05 | 23% -30% Cr White Iron | I-impeller, ii-liners, expeller, umsesane wokukhupha, ibhokisi yokuhlohla, umqala, ufake iplate yefreyimu |

| A07 | 14% -18% Cr White Iron | Impeller, iiliners |

| A49 | 27%-29% yeCr Low Carbon White Iron | Impeller, iiliners |

| A33 | I-33% yoKhukuliseko lwe-Cr kunye ne-Ayini eMhlophe yokuNxhathisa ukuRhakala | Impeller, iiliners |

| I-R55 | Irabha yendalo | Impeller, iiliners |

| I-R33 | Irabha yendalo | Impeller, iiliners |

| I-R26 | Irabha yendalo | Impeller, iiliners |

| R08 | Irabha yendalo | Impeller, iiliners |

| U01 | Polyurethane | Impeller, iiliners |

| G01 | Intsimbi eNgwevu | I-Frame plate, i-cover plate, i-expeller, i-ring expeller, indlu yokuthwala, isiseko |

| D21 | Intsimbi yentsimbi | Ipleyiti yefreyimu, ipleyiti yokugubungela, indlu yokuthwala, isiseko |

| E05 | Intsimbi yeCarbon | Umphini |

| C21 | Intsimbi engatyiwa, 4Cr13 | Umkhono weshaft, umsesane wesibane, isithinteli sesibane, iringi yentamo, ibholithi yedlala |

| C22 | iStainless Steel, 304SS | Umkhono weshaft, umsesane wesibane, isithinteli sesibane, iringi yentamo, ibholithi yedlala |

| C23 | iStainless Steel, 316SS | Umkhono weshaft, umsesane wesibane, isithinteli sesibane, iringi yentamo, ibholithi yedlala |

| S21 | Butyl irabha | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Nitrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | IHypalon | I-Impeller, i-liners, i-expeller ring, i-expeller, i-joint rings, i-joint seal |

| S44/K S42 | Neoprene | I-Impeller, i-liners, i-Joint rings, i-joint seal |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |