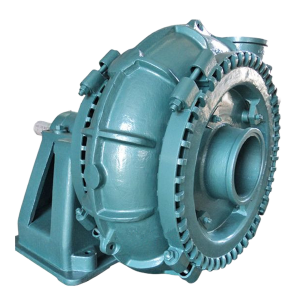

I-TPSP / SPRPPPPR ye-pumpry ye-slide

I-TPSP / SPRPPPPR ye-pumpry ye-slideyenzelwe izicelo ezifuna ukuthembeka okukhulu kunye nokuqina kunenkqubo ethe nkqo ye-Pumps. I-Elastomer ngokupheleleyo okanye isinyithi esinzima. Akukho zibherheli ezinamachaphaza okanye ukupakisha. Uyilo oluPhezulu lokuNikezela kabini. Ubude obufikelelweyo obungaphantsi komhlaba kunye ne-Agitor ye-suction ifumaneke. I-TSPP / SPR PRPR ye-SPR Purt Pump ilungele ukuphathwa okuqhubekayo okuqhubekayo kunye nolwelo oluphangaleleyo kunye nolwelo oluqhelekileyo kunye ne-sutird ngelixa i-pumed okanye imingxunya.

Iimpawu zoyilo

√ Ukunxiba okuncinci, ubuncinci

Izinto ezimanzi ziyafumaneka kuluhlu olubanzi lwamafutha kunye ne-elastomes, apho i-WIRORALS inyula indibaniselwano ephezulu yokuthintela i-abrasion kunye nokunganyangeki okukhulu kwaye ukungcungcutheka okukhulu kudibana khona.

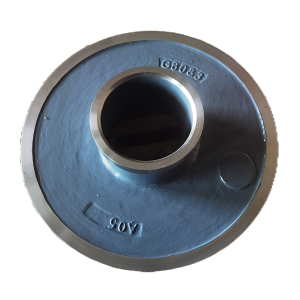

I-Abrasion enganyangekiyo i-A05 Allocy®.

I-A49 I-A49 I-A49 I-ALHERCHROME ALTHREAL.

• I-colosion-i-steist engachaphazeli.

I-Elastomers yendalo neyokwenziwa.

Akukho ntsizana

I-shaft yomeleleyo inqanda imfuno yezithuthuko eziphantsi eziphantsi - ezihlala zingumthombo wokuphazamiseka kwangaphambili.

• I-roller ende ende, ngaphezu kwendawo yokuphakamisa.

• Akukho zibheringi ezinamachaphaza.

• I-Labyrinthrinth / Flilider ethutha ukhuseleko.

• I-rigid, i-shaft enkulu yedabi.

Akukho mingxunya yokutywina

Uyilo lwe-vertical alcielical yoyilo olufunayo akukho tywina.

Akukho kuqondakalayo

I-Iprist kunye nezantsi koyilo ilungele imeko "ye-snore".

√ Umngcipheko omncinci wokuthintela

Ii-inlets ezihloliweyo kunye neendinyana ezinkulu ze-IMPORMuls zinciphisa umngcipheko weebhloksi.

√ Iindleko zamanzi ezincedisayo

I-vernication yoyilo olubi ngaphandle kwe-gland okanye iibherithi ezinamanzi zithintela imfuno ye-gland okanye ithwele amanzi agudileyo.

I-TSP / STRPPRVerry pumpry pumpryIiparamitha zokusebenza

| Imodeli | Ukutshatisa amandla p (kW) | Umthamo Q (M3 / h) | Intloko h (m) | Isantya n (r / min) | EFF.η (%) | I-Impholler dia. (mm) | I-max.Paliles (mm) | Ubunzima (ikg) |

| I-40PV-tsp (R) | 1.1-15 | 7.2-29 | 4-28.5 | I-1000-2200 | 40 | 188 | 12 | I-300 |

| I-65QV-TSP (R) | 3-30 | 18-11 | 5-31.5 | I-700-1500 | 60 | 280 | 15 | I-500 |

| I-100RV-tp (R) | 5.5-75 | 40-289 | 5-36 | I-500-1200 | 62 | 370 | 32 | I-920 |

| I-150sv-tp (r) | I-11-110 | I-108-576 | 8.5-40 | I-500-1000 | 52 | I-450 | 45 | 1737 |

| I-200sv-tp (r) | I-15-110 | I-180-890 | 6.5-37 | I-400-850 | 64 | I-520 | 65 | Ngama-2800 |

| I-250TV-TSP (R) | 185-200 | 261-10899 | 7-33.5 | I-400-750 | 60 | I-575 | 65 | I-3700 |

| I-300TV-TSP (R) | I-22-200 | 288-1267 | 6-33 | I-350-700 | 50 | I-610 | 65 | I-3940 |

I-TSP / STRPPRVerry pumpry pumpryIzicelo ze-S

Impompo ye-TPPP / ye-spprical prourry ifumaneka kuluhlu olubanzi lwe-SEARIT SEIRS ukuze ilungele ukusetyenziswa kweempompo. I-TSPP / ye-PSPR SUMP ibonisa ukuthembeka kwabo kunye nokusebenza kakuhle kwelizwe: Ukulungiswa kwe-minerals, ukuqhubekeka kwamachiza, ukuphatha itanki kunye ne-right kunye nendawo yokuhlambela. I-TPPR / SPR Pump yoyilo yentsimbi yentsimbi (i-TSP) okanye i-Elastomer egutyungelweyo (i-Tspr) iyenza ukuba ilungele ukusebenza kwaye i-substries eqinileyo, i-subring ye-subres, i-snore "eqhubekayo, inyanzelisa i-shafts engxamisekileyo.

* I-TPP verry pumps kunye ne-spayishini ingena ngaphakathi kwi-Warman® ye-SPRY SPRY STOPY STOPS kunye neendawo eziphakamileyo.

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |