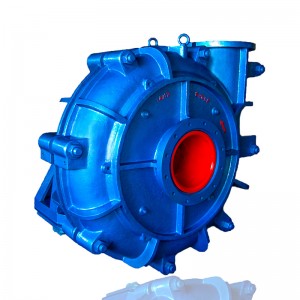

I-16/14TU-THR yeRubber Lined Slurry Pump, Uluhlu olupheleleyo lweemodeli zempompo

16/14TU-THR yeRubber Lined Slurry Pumpisiphelo sokufunxa, i-case-case, i-centrifugal slurry pumps esete umgangatho wehlabathi we-abrasive duty duty abrasive applications pumping.Ngama-diameters amakhulu e-shaft, ii-assemblies ezithwala umsebenzi onzima kunye nomthamo oqinileyo wokupompa i-slurry, iimpompo ze-16/14 ze-slurry zibonelela ngeendleko ezingabizi kwaye zilungele enye indlela kwixesha elide lokukhokela kunye nobunzima obunxulumene nokusebenza kunye nezizwe ezininzi ezinkulu.

Iimpawu zoyilo:

√ 16/14 TU THR Pump iindawo ezimanzi zenziwe ngerabha.

√ 16/14 TU THR Pump ethwele indibano yendibano sebenzisa ubume becylindrical, ukulungelelanisa isithuba phakathi kwe-impeller kunye ne-front liner ngokulula.Zinokususwa ngokupheleleyo xa zilungiswa.Ukuthwala indibano sebenzisa ukuthambisa igrisi.

√ Isitywina seshafti singasebenzisa isitywini sokupakisha, isitywini esikhuphayo kunye nesitywina esisebenza ngoomatshini kuyo yonke impompo eludaka.

√ Isebe lokukhutshelwa kwamanzi linokumiswa ngezithuba zama-45 degrees ngesicelo kwaye lilungelelaniswe kuzo naziphi na iindawo ezisibhozo ukuze zihambelane nofakelo kunye nokusetyenziswa kwindawo yalo yokusebenza.

√ Kukho iintlobo zokuqhuba, ezifana ne-V belt drive, i-gear reducer drive, i-fluid coupling drive, kunye nezixhobo zokuqhuba ukuguqulwa kwamaza.

√ Ukusebenza okubanzi, i-NPSH elungileyo kunye nokusebenza okuphezulu.

√ Impompo eludaka enerabha inokufakwa kuthotho lwezigaba ezininzi ukuhlangabezana nokuhanjiswa komgama omde.

16/14 STTHRIiParameters zokuSebenza zePump yeRubber Lined:

| Umzekelo | Max.Amandla (kw) | Izinto eziphathekayo | Sula ukusebenza kwamanzi | Impeller Inombolo yeVane. | |||||

| Umgca | Impeller | Umthamo Q (m3/h) | Intloko H (m) | Isantya n (rpm) | Eff.η (%) | NPSH (m) | |||

| 16/14ST-THR | 560 | Irabha | Irabha | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 5 |

ULungiselelo lokutywina lweempompo zeRubber ezinemigca yerabha:

Ukupakisha itywina

Njengolunye lwezitywina ezisetyenziswa ngokuqhelekileyo kwii-shafts ezijikelezayo, isitywina sokupakisha sinokuza kunye ne-low-flush okanye ilungiselelo lokugungxula elipheleleyo elisebenzisa ukugungxula kwamanzi ukuthintela imidiya ekubalekeni indlu yempompo.Olu hlobo lwesitywina lufanelekile ukusetyenziswa phantsi kwazo zonke iimeko zokupompa.Kwiimeko apho izinto eziqinileyo ezidlekayo okanye ubushushu obuphezulu bunokuqubisana nazo, iTeflon okanye i-aramid fiber isetyenziswa njengempahla yokupakisha idlala.Kwiimeko eziphezulu ze-abrasion, umkhono we-ceramic shaft uyafumaneka.

Isitywina se-Centrifugal - uMxolisi

Indibaniselwano ye-impeller kunye ne-expeller idala uxinzelelo olufunekayo ukutywina ngokuchasene nokuvuza.Kunye ne-gland seal okanye i-lip seal esetyenziswa njengetywina lokuvala, olu hlobo lwesitywina lunokusingatha iimfuno zokutywinwa kwizicelo apho itywina eligungxula ngokupheleleyo lingenakwenzeka ngenxa yokungabikho kwamanzi kwisiza, okanye ukutywinwa kwamanzi kuvunyelwe. ukungena ngaphakathi kwigumbi lokumpompa ukungcungcuthekisa udaka.

Mechanical itywina

Impompo yerabha enomsebenzi onzima wodaka isebenzisa uyilo lokutywina lobungqina bokuvuza obuvumela ukufakela kunye nokutshintshwa.Ezinye iintlobo zokutywinwa koomatshini ziphakathi kokhetho olulungele impompo eludaka kwizicelo ezahlukeneyo zokumpompa.

Sikwasebenzisa i-ceramic ekhethekileyo kunye ne-alloys zamandla aphezulu kunye nokuqina kwiindawo eziphantsi kwengxabano.Uyilo olulodwa kunye nokulungelelaniswa okungenamthungo phakathi kwetywina lomatshini kunye negumbi lokutywina libonelela ngokugqwesa ukuxhathisa ukubetha kunye nokothuka okuqinisekisa ukusebenza kwayo phantsi kwezona meko zinzima.

Iinketho zoThunyelo lwePump yeRubber enelinen:

Uhlobo lwe-DC: I-shaft ye-output ye-motor iqhagamshelwe ngokuthe ngqo kwi-shaft yongeniso yempompo ngokusebenzisa i-coupler yepompo.Olu hlobo loqhagamshelwano lufanelekile kwizicelo apho isantya sempompo ye-slurry sifana naleyo ye

imoto.

Uhlobo lwe-CV: Impompo iqhutywa libhanti eliqhagamshelwe kwi-crankshaft ye-injini.Le ndlela yokudibanisa ivumela ukugcina indawo, ukufakwa lula, kunye nokulungiswa ngokukhawuleza kwesantya sokumpompa.I-motor igxininiswe kwisakhelo senkxaso ye-motor ebekwe kwinkxaso yokuthwala ngaphezu kwempompo ye-slurry.

Uhlobo lwe-ZV: Olunye uhlobo lokuqhuba ibhanti oluvumela uhlengahlengiso olulula lwesantya sokumpompa.I-motor igxininiswe ngokuthe ngqo kwinkxaso yokuthwala.Le ndlela yofakelo ifanelekile kwiimotor ezinamandla amakhulu ehashe kunokuba kunokwenzeka ngohlobo lofakelo lweCV.Ngenxa yokufakwa kwemoto kwinkxaso yokuthwala, le ndlela inceda ukugcina indawo yofakelo.

Uhlobo lwe-CR: Olu hlobo lokuqhuba ibhanti lwenza kube lula ukulungisa isantya sokumpompa.Ufakelo luvumela zombini i-motor kunye nepompo yodaka ukuba ilungiswe phantsi.I-motor ifakwe kwicala lempompo.Le ndlela yokufakela ifanelekile kwiinjini zamandla amakhulu.

Izicelo zeempompo eziludaka ezinerabha ezinemigca:

Iimpompo zerabha ezinerabha ezinodaka zisetyenziswa ngokubanzi kwizityuli ezimanzi, ukukhutshwa kwe-SAG mill, ukukhupha ilitye lokusila, ukukhupha intonga, i-Ni acid slurry, isanti erhabaxa, intsimbi erhabaxa, iphosphate matrix, imineral concentrate, imidiya enzima, ukudilizwa, umzantsi/uthuthu lwempukane, ikalika. ukugaya, isanti yeoli, isanti yamaminerali, ii-tailings ezintle, i-phosphoric acid, amalahle, i-flotation, i-sugar beet, inkqubo yeekhemikhali, i-pulp kunye nephepha, i-FGD, inkunkuma yamanzi njl.

Phawula:

16/14 TU THR iimpompo eziludaka ezinerabha ezinemigca kunye nezinto ezisetyenziswayo ziyakwazi ukutshintshatshintsha kuphela nge-Warman® 16/14 TU AHR yerabha eneempompo ezinodaka kunye nezincedi.

TH Cantilevered, Horizontal, Centrifugal Slurry Imathiriyeli yeMpompo:

| Ikhowudi yezinto eziphathekayo | Inkcazo yezinto | Amalungu eSicelo |

| A05 | 23% -30% Cr White Iron | I-impeller, ii-liners, expeller, umsesane wokukhupha, ibhokisi yokuhlohla, umqala, ufake iplate yefreyimu |

| A07 | 14% -18% Cr White Iron | Impeller, iiliners |

| A49 | 27%-29% yeCr Low Carbon White Iron | Impeller, iiliners |

| A33 | I-33% yoKhukuliseko lwe-Cr kunye ne-Ayini eMhlophe yokuNxhathisa ukuRhakala | Impeller, iiliners |

| I-R55 | Irabha yendalo | Impeller, iiliners |

| I-R33 | Irabha yendalo | Impeller, iiliners |

| I-R26 | Irabha yendalo | Impeller, iiliners |

| R08 | Irabha yendalo | Impeller, iiliners |

| U01 | Polyurethane | Impeller, iiliners |

| G01 | Intsimbi eNgwevu | I-Frame plate, i-cover plate, i-expeller, i-ring expeller, indlu yokuthwala, isiseko |

| D21 | Intsimbi yentsimbi | Ipleyiti yefreyimu, ipleyiti yokugubungela, indlu yokuthwala, isiseko |

| E05 | Intsimbi yeCarbon | Umphini |

| C21 | Intsimbi engatyiwa, 4Cr13 | Umkhono weshaft, umsesane wesibane, isithinteli sesibane, iringi yentamo, ibholithi yedlala |

| C22 | iStainless Steel, 304SS | Umkhono weshaft, umsesane wesibane, isithinteli sesibane, iringi yentamo, ibholithi yedlala |

| C23 | iStainless Steel, 316SS | Umkhono weshaft, umsesane wesibane, isithinteli sesibane, iringi yentamo, ibholithi yedlala |

| S21 | Butyl irabha | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Nitrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | IHypalon | I-Impeller, i-liners, i-expeller ring, i-expeller, i-joint rings, i-joint seal |

| S44/K S42 | Neoprene | I-Impeller, i-liners, i-Joint rings, i-joint seal |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |