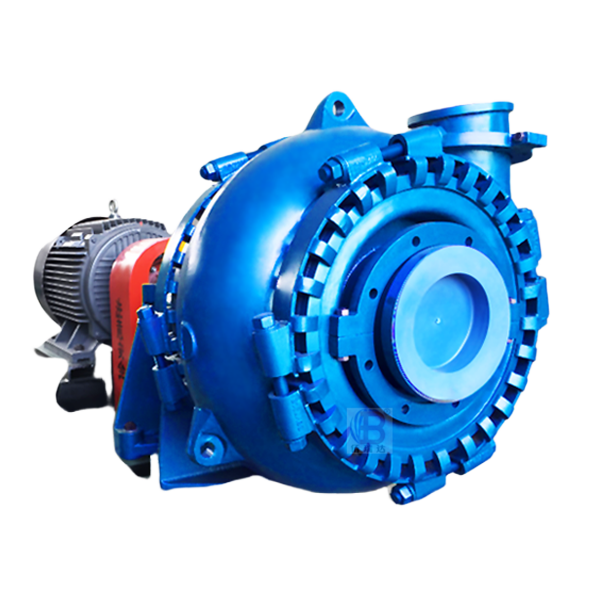

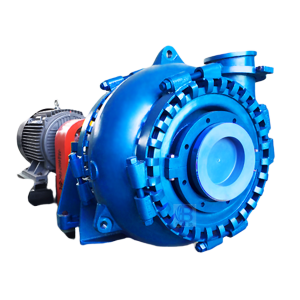

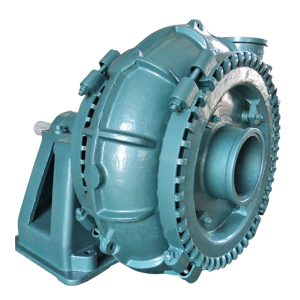

I-TG GOLL PUP PUPUP YOKUZIPHATHA KWEMPAHLA YOKUGQIBELA

I-TG / TGH SADImpompo yeGravelszenzelwe ngokukodwa ukutyibilika okuqhubekayo kwe-tyrider ethe tyaba, iqhekeza kunye nesanti. Ngobungakanani obubanzi bobungakanani. Ukwazi ukuphatha amasuntswana amakhulu kwiziphumo eziphezulu zokusebenza kakuhle kwiziphumo zexabiso eliphantsi lobunini. Iprofayili enkulu yevolumu yangaphakathi ye-cing inciphise i-velocies enxulumene nokonyusa ubomi becandelo.

Iimpawu zoyilo

√ I-ring ekhethekileyo ye-clagmer ye-Clamps kwiiyunithi ezikhulu kwaye iqinile kwiimpompo ezincinci, ziququzelela ukujikeleza kwe-casing kuyo nayiphi na ikona, ukunciphisa imfuno yokutya okuphezulu. Ulondolozo oluncinci luyafuneka.

√ I-Imphol-Mperlion Danes inciphisa uxinzelelo lwe-gland kunye nokungena kokugxila okuphezulu kwezinyibilikisi kwindawo ye-gland. Ukusebenza kakuhle kuyagcinwa ngokunciphisa i-curcimetion.

√ I-vines ye-Imples ye-Imple ebiweyo ivumela ukuphathwa kwamasuntswana amakhulu aphezulu. Uyilo olukhethekileyo lwe-chenti kunye nokutywina i-vanes Thumela i-flusives selids kwi-insusion kwimvelaphi yokutywina.

√ I-Chedi enkulu, eyomeleleyo yenzelwe ukunciphisa i-velocies yangaphakathi ekhokelela kwilahleko esezantsi kwaye iphuculwe i-cheng god. I-Cheding yenziwa ngezinto ezintathu zokunciphisa ixesha lokugcina kunye neendleko ezinxulumene noyilo lwe-Onepriece. (Ngaphandle kwe-6/4 DG enezinto ezimbini)

√ Rima igrisi enzima ye-taper i-taper roller enxibe iindibano ifakwe njengomgangatho. I-shaft ephezulu ye-digid ye-diaft eqinileyo encitshisiweyo incitshisiweyo incitshisiweyo incipha kunye nokuntywila phantsi kwazo zonke iimeko zokuqinisekisa ukusebenza kwasimahla. Izinto ezingaqhelekanga zenkonzo eziphezulu zenkonzo zenza ukuba indibano ithwale zonke ii-radial kunye ne-axial sus.

√ Iqela elikhethekileyo "-10" (i-DASH 10) Indibano yeresiphi enamatywina, i-piston ephindwe kabini kunye ne-pistor yangaphandle ene-laibrints i-laibrints ye-laib

Tg / tghhImpompo ye-sand gumpIiparamitha zokusebenza

| Imodeli | UMax. Amandla p (kW) | Umthamo Q (M3 / h) | Intloko h (m) | Isantya n (r / min) | I-EFF. η (%) | I-NPS (m) | I-Impholler dia. (mm) |

| I-6 / 4D-tg | 60 | 36-250 | 5-52 | I-600-1400 | 58 | 2-5.5 | 378 |

| I-6 / 4e-tg | I-120 | 36-250 | 5-52 | I-600-1400 | 58 | 2-5.5 | 378 |

| I-8 / 6e-tg | I-120 | I-126-576 | I-6-45 | I-800-1400 | 60 | 3-4.5 | 391 |

| I-10 / 8s-tg | I-560 | 216-936 | I-8-52 | I-500-1000 | 65 | I-3-7.5 | I-533 |

| I-10 / 8s-tghh | I-560 | I-180-1440 | I-24-80 | I-500-950 | 72 | 2.5-5 | I-711 |

| I-10 / 8F-tg | 260 | 216-936 | I-8-52 | I-400-800 | 65 | I-3-7.5 | I-533 |

| I-12 / 10F-tg | 260 | I-360-1440 | I-10-60 | I-350-700 | 65 | 1.5-4.5 | 667 |

| I-12 / 10G-tg | I-600 | I-360-1440 | I-10-60 | I-400-850 | 65 | 1.5-4.5 | 667 |

| I-12 / 10G-tghh | I-600 | 288-2808 | I-16-80 | I-350-700 | 73 | 2-10 | I-950 |

| I-14 / 12g-tg | I-600 | I-576-3024 | I-8-70 | I-300-700 | 68 | 2-8 | I-864 |

| I-14 / 12t-tg | 1200 | I-576-3024 | I-8-70 | I-300-700 | 68 | 2-8 | I-864 |

| I-16 / 14g-tg | I-600 | I-720-3600 | I-18-45 | I-300-500 | 70 | 3-9 | I-1016 |

| I-16 / 14t-tg | 1200 | I-720-3600 | I-18-45 | I-300-500 | 70 | 3-9 | I-1016 |

| I-16 / 14tu-Tghh | 1200 | 324-3600 | 26-70 | I-300-500 | 72 | 3-6 | I-1270 |

| I-18 / 16tu-tg | 1200 | I-720-4320 | I-12-48 | I-250-500 | 72 | 3-6 | I-1067 |

I-TG / TGH SAD SANBONT ZEPHUMI ZESIFUNDO

I-TG / TGH-SANDY SANDY STADS & Impompo yempompo eqhelekileyo ithathe imisebenzi ephezulu yentloko, iipumps zegrabile zilungele i-Dredger, i-Dereds, i-Dereds, i-Dereying, iMineli ye-quipeline yoFundo kunye nemisebenzi emide yemifanekiso.

PHAWULA:

* I-TG Gumps kunye ne-spayishini ingena ngaphakathi kwi-warman®Gupes ze-gravel kunye neendawo zokugcina.

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |