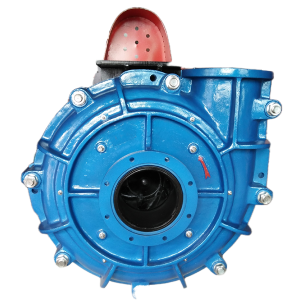

I-6 / 4e-Toub ye-pumpry yerabha, iguqulwe nge-warman pumps

I-6 / 4e-tem thapry yerabha ye-slickI-cantred, ethe tyaba, i-centrifugal ene-pumpry ye-pumpry ye-slide.Bing zenzelwe ukuphatha irabha. kunye netywina lomatshini.

Iimpawu zoyilo:

I-√bering indibano-i-shaft enkulu ye-overter ene-overkhang inciphisa kwaye inegalelo kubomi obude obuhluphekayo

I-√liners-i-liners eqhotyoshelweyo inyibilikisiwe, ingabinayo i-cirling yokuncamathisela ngokuchanekileyo kunye nokuncitshiswa kwezolondolozo. I-Litard yentsimbi iguqukayo kwi-raber rabor ibuye umva onke amakhonkco.

I-halves ye-halves yokuphosa okanye i-ductile yentsimbi eqinileyo yokuqinisa iimbambo zangaphandle zibonelela ngezakhono eziphezulu zokusebenza kunye nomlinganiselo owongezelelweyo wokhuseleko.

I-√imdler-ngaphambili nangasemva i-shrouds iphumele i-vanes enciphisa i-revoirccounts.hard inyanzelise i-impuku yerabha.

I-√throatbush-i-tyring incitshisiwe kwaye igcinwe lula ngokusetyenziswa kobuso obutofotofo ukuba kuvumeleke ukuba ulungelelwaniso olufanelekileyo ngexesha lendibano kunye nokususwa ngokulula.

Isakhelo se-√one-i-quast isakhelo se-radds i-cartridge yohlobo lwe-cartridge kunye neNdibano ye-Shoft i-Shaft.

I-6/4 i-Touch Toub yerabha ye-pumpry yempompo yokusebenza:

| Imodeli | UMax. Amandla (kW) | Izixhobo | Ukucoca amanzi | Umthengisi I-vaney. | |||||

| Liner | Umthengisi | Umthamo Q (M3 / h) | Intloko h (m) | Isantya n (i-RPM) | I-EFF. η (%) | I-NPS (m) | |||

| I-6 / 4E-Ahr | I-120 | Irabha | Irabha | I-144-324 | I-12-45 | I-800-1350 | 65 | I-3-5 | 5 |

I-Rubber Lien Pumpry Pumpry Pumpry Pumpry Pumps zePumpry:

I-čiron ore yokunxiba

Isityalo se-√copper

√Goild isityalo sam soxinzelelo

Isityalo se-√molybDenum se-√molybDenum

Isityalo se-√potash isityalo se-√potash

Izityalo ezisebenzayo zemineral

Umzi-mveliso we-√alumina

I-√coal ye-√OHIY

√

I-Dlosand Embaunt

Imveliso yezinto ezibonakalayo

Umzi-mveliso we-√chemical

Amashishini aphezulu

Phawula:

I-6/4 i-Toper Tops yerabha yerabha kunye neenxalenye zitshintshile i-warman ®6 / 4 et yoThululo yerabha enamafutha kunye neenxalenye.

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |