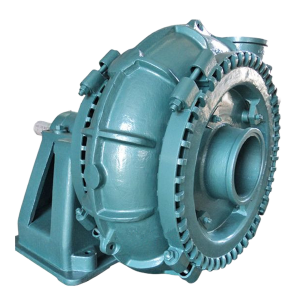

I-250TV-tp verry verry pumpry

I-250TV-tspVerry pumpry pumpryAkukho zibherings ezinamachaphaza okanye amatywina anemithwalo enesidima enesidima, ezilungele iintlobo ezahlukeneyo zompompo zempompo. Ezi pumps zisebenza kakuhle kwiimeko ezahlukeneyo ze-SUP, kwaye zinokusetyenziswa ngokulula kwi-Dewater Dewaters okanye amanye amaqonga empompo.

Iimpawu zoyilo

• Indibano ekhokelayo - ithwele, ishafti kunye nomyinge wezezindlu omkhulu kakhulu ukuthintela iingxaki zokusebenza kwe-call yesantya sokuqala.

Amacandelo athathwe ngegrisi kwaye atywinwe kwilebhu. Umphezulu ucocwe ngegrisi kwaye ezantsi ikhuselwe ngendlela ekhethekileyo. Ii-Brings ezingaphezulu okanye zokuphelisa ukuphelisa uhlobo lwe-roller roller roller roller roller kunye neebheri eziphantsi ziingqengqele kabini ezinamathele ezantsi. Esi sigqibo seNtsebenzo esiPhakamileyo kunye ne-shaft ekhutshiweyo ayifuni kukhala kwamanzi aphantsi komhlaba.

• Indibano yeKholam - idityaniswe ngokupheleleyo kwintsimbi ethobekileyo. Imodeli ye-SPR ngumgqomo we-Elastomer ogutyungelweyo.

Ukukhawulelana-kune-bolt elula-kunamathisela kwisiseko sekholamu. Ifakwe kwi-alloy enganyangekiyo ye-SP kwaye isuka kwi-Elastomer ye-Elastomer kwi-SPR.

• Impembelelo-iMpensers ePhezulu (i-Enter kunye ne-Inlets ezantsi) ivelisa imithwalo esezantsi ye-axial kwaye inomthwalo onzima wokunganyangeki kwe-slids ephezulu kunye nokuphatha izinyibilikisi ezinkulu. Nxiba i-Alfy ye-Alfy, i-Polyurethane kunye ne-implated ye-Elastomer ye-Elastoment itshintshiwe. Ngexesha lendibano, i-impleller ihlengahlengiswa nge-axintse ngokuphosa nge-roeket ye-garket yangaphandle phantsi kwesiseko sesihlalo esinezihlalo. Awukho olunye uhlengahlengiso olufunekayo.

• Isiseko esiphezulu-ngentsimbi yentsimbi, i-snap-kwi-elastomer okanye i-polytorthane ye-SP kunye ne-SPR Pumps. I-Strainers ifanelekile kwikholamu.

• Isinyithi esisezantsi - isinyithi esibiweyo okanye i-polyurethane ye-SP, i-snap-in elastomer ye-PRR.

• Ukulahla umbhobho-intsimbi ye-SP, i-Elastomer igutyungelwe i-SPR. Zonke iindawo ezimanzi ezimanzi zikhuselwe ngokupheleleyo.

• Ibhetri enamanzi-ayikho

• I-Agatotor-Inketho yoNxibelelwano yaNgaphandle yaNgaphandle ifakwe kwimpompo. Ngenye indlela, i-squirrer yomatshini ifakwe kwi-shaft yongezwa kwi-Impleller Hole.

• Izixhobo-iimpompo zinokwenziwa kwizinto ezinganyangekiyo nezonyango.

I-250TV-tspVerry pumpry pumpryIiparamitha zokusebenza

| Imodeli | Ukutshatisa amandla p (kW) | Umthamo Q (M3 / h) | Intloko h (m) | Isantya n (r / min) | EFF.η (%) | I-Impholler dia. (mm) | I-max.Paliles (mm) | Ubunzima (ikg) |

| I-250TV-TSP (R) | 185-200 | 261-10899 | 7-33.5 | I-400-750 | 60 | I-575 | 65 | I-3700 |

I-250 yeTV ye-TV ebike i-pump yokungaziphathi kakuhle

• imigodi

Ukulungiswa kwezimbiwa

Ulwakhiwo

• Imichiza kunye nokuchumisa

• Ukuveliswa kwamandla

• Ukukhupha ibhola

• I-ROD Glima

• I-SAG MGRORT

• Imisila elungileyo

• Iflotation

INKQUBO YOKUGQIBELA YOKUGQIBELA

Iiminerali zigxila

• I-Mineral Sands

Phawula:

I-250 yeTV-tsp verry versing kunye neendawo zitshintshiselana kuphela nge-Warman® 250 i-TV-SP-SPRY STURS Pumpry kunye neendawo zokugcina.

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |