I-16 / 14tu

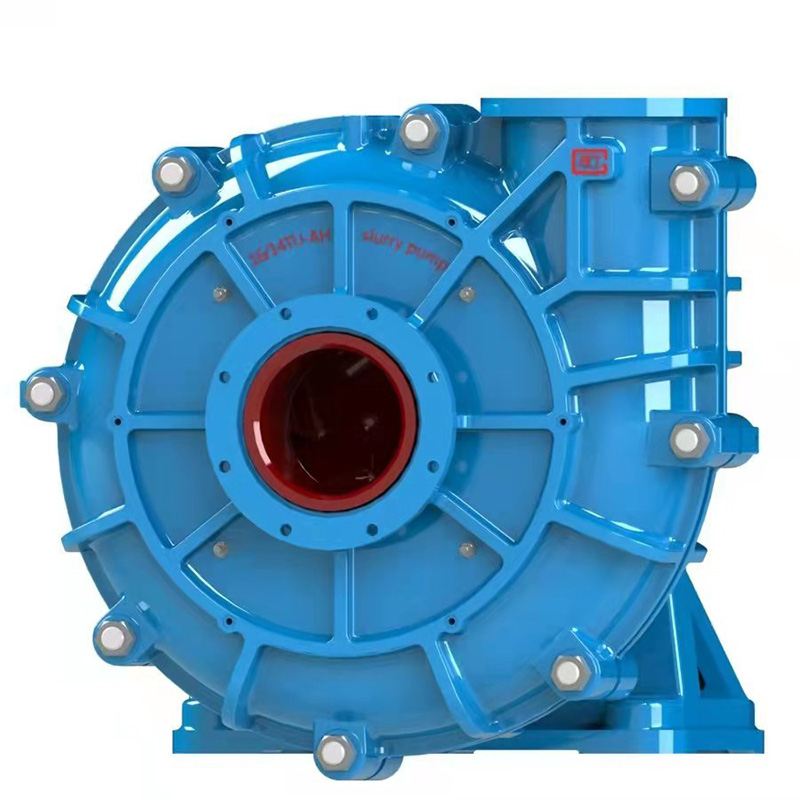

Inkcazo

Uchungechunge lwe-T Th ngamanqanaba angatshatanga, ukungcungcutheka kodwa, i-cantile ye-shol, i-shonter cemporicugal ye-cetroleagal. Ukuhamba kwe-Milling Guilry kunye neesilayidi ze-surrry.Bey ikakhulu zisetyenziselwa ukuphakama, i-cyclone ixhoba, i-sand yokufuduka, i-SGD, imithombo yeendaba, njl.

Ububanzi: 25mm ~ 450mm

Amandla: 0-2000kw

Ixabiso lokuhamba: 0 ~ 5400㎥ / h

Intloko: 0 ~ 128m

Isantya: 0 ~ 3600rpm

Izixhobo: i-chrome ephezulu okanye irabha

Isicelo

1, U-Slarry uhlala ehlelwa ngokobungqina beenyibilikisi. Ukwahlulahlulwa kobunjineli bokutyibilika kunzima kakhulu kwaye kubandakanya uxinzelelo, ubungakanani bentshukumo, ubume kunye nobunzima ukuze bamisele ubugqwirha. Ukukhetha ubunjineli beempompo zesilayidi, i-slirry ihlelwe njengeklasi yoku-1, iklasi 2, iklasi 3 kunye neklasi 4.

2, Ukukhethwa kweempompo zesilayidi kunokuba nzima kunokhetho lweempompo zamanzi kunye nolwelo. Izinto ezininzi kunye nezilungiso kwinqaku lomsebenzi zichaphazela i-brake yamahashe kunye nokunxiba. Isaphulelo se-Peipheral ye-Impleller yenye yeempawu eziphambili kunye nokuhlelwa kweempompo zesilayidi. Isantya kufuneka sihambelane nohlobo lohlobo lwesilayidi (ukwahlulahlulahlulahlulwa kwe-arasion) ukuze kugcinwe ubomi obusengqiqweni kwinkonzo ngenxa yokuphaphanyiswa okuphezulu kweenyibiliki.

Shijiazhhuang Rump Pump Co.ltd

I-abrasion ixhaphake nge-centrifugal yesanti ye-slicerry ye-slide

I-thricigal ye-centrifontal or Pumpy Pumpry Pumpry yenzelwe ukuphatha kakhulu, ukungcungcutheka okuphezulu ngokunxibisa ubomi ngelixa ugcina impumelelo ngexesha lomjikelo obonelela ngexabiso elipheleleyo lokusebenza.

Izicelo

I-ratrifugal ye-centrifugal enzima ye-Altray Line impompo ye-pumpry ye-sumps ye-pumps yi-pumpcrive / i-gurity sutcries ethatyathwayo kwi-cyclone yokutya ukubuyisa izityalo kunye nezinye izicelo zemveliso, ngamanye amaxesha. Ingasetyenziselwa ukuntywila kwii-laqoons zokuseta kunye nokupeyimba kodaka olunxila njl njl njl.

| ·Ukulungiswa kwezimbiwa | ·Ukuphatha | ·I-cyclone itya | ·Inkonzo yeSolide |

| ·Ukulungiswa kwamalahle | ·Ukuphatha amanzi amdaka | ·I-crushers emanzi | ·Ukulungiswa kwe-Aggregate |

| ·Ibhola yebhola yebhola yebhola | ·I-SAG MGRORT | ·I-Rod Milli Groct | ·I-primar elungileyoy migagukungcungcutheka |

| ·Imisila | ·Ukugaya okwesibini | ·Inkunkuma yenkunkuma | ·Phosphoric acid |

| ·I-pulp kunye nephepha | ·Ukuqhubekeka kokutya | ·Imisebenzi eyoyikisayo | ·Ukulungiswa kweMizi-mveliso |

Inqaku

1. Ubume be-cylindrical yeNdibano ephetheyo: Elula ukuhlengahlengisa indawo phakathi kwe-impeller kunye ne-liner ngaphambili kwaye inokususwa ngokupheleleyo;

I-2. I-Anti-I-Abrasion Imanzi: Iinxalenye ezimanzi zingenziwa ngengcinezelo yerabha. Zitshintshile ngokupheleleyo ngamacandelo emanzi.

3. ICandelo le-Ecreat linokulungiswa nangayiphi na indawo ezisibhozo kwi-degresi yama-45;

I-4. Iindidi ezahlukeneyo ze-drive

5. Itywina leShaft lisebenzisa itywina lokupakisha, itywina lomthengisi kunye netywina lomatshini;

Inkqubo ihamba

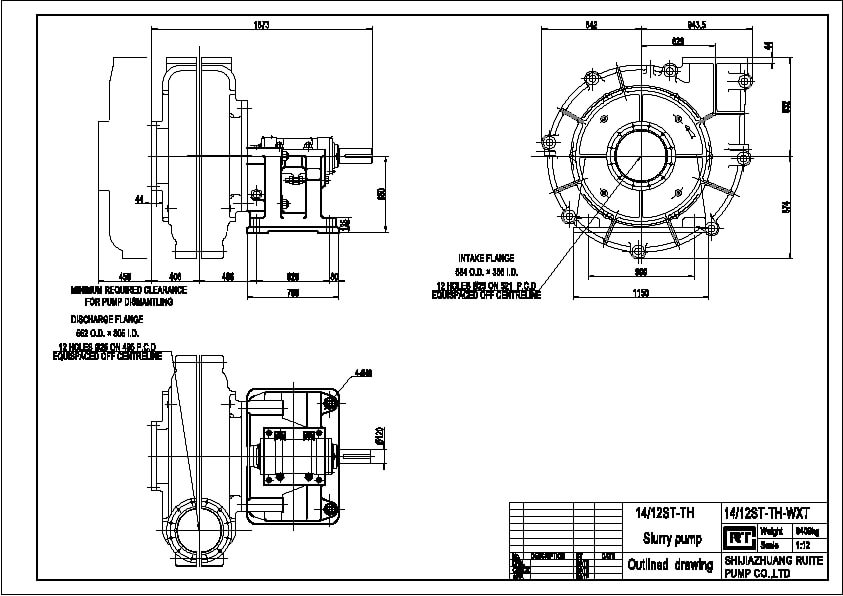

Iprofayile yokuGqibela

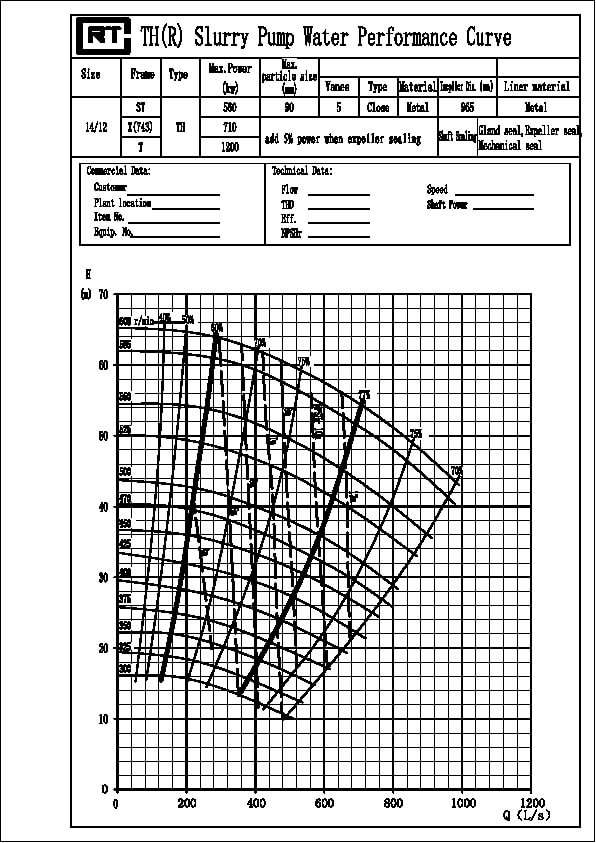

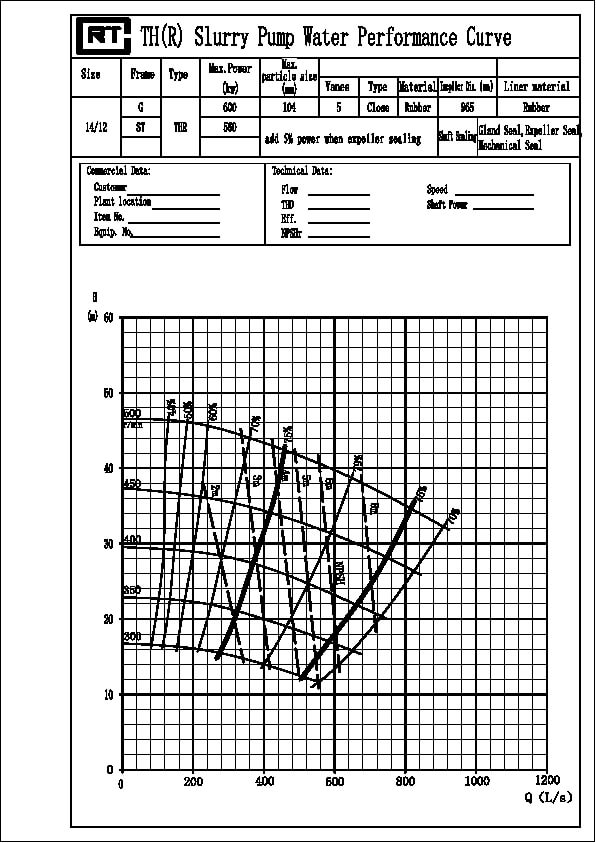

Iinkcukacha ezithe kratya

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

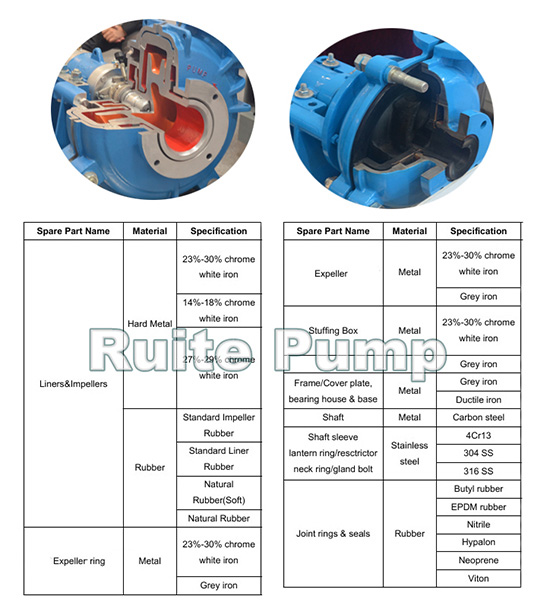

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |