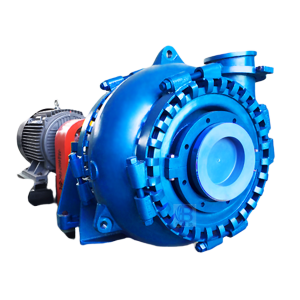

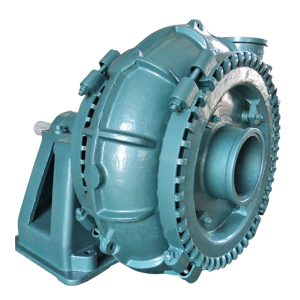

I-12 / 10G-tg grevel impompo yesanti yokutsala umlambo

I-12x10g-tg impompo yegrabileyenzelwe ngokukodwa ukutyibilika okuqhubekayo kwe-tyring etyhutyha kakhulu, ngobukhulu obubanzi bodwa. Ukwazi ukuphatha amasuntswana amakhulu kwiziphumo eziphezulu zokusebenza kakuhle kwiziphumo zexabiso eliphantsi lobunini. Iprofayili enkulu yevolumu yangaphakathi ye-cing inciphise i-velocies enxulumene nokonyusa ubomi becandelo. 12 × 10Impompo ye-sand gumpS zisetyenziselwa ukuhambisa ngokutyibilikayo kwimigodi, ukuqhuma kwe-sholusge kwinyibilikisi yentsimbi, ukuqhayisa eDredger naseMilanjeni nakwamanye amasimi.

Iimpawu zoyilo:

Imodeli ephezulu ye-hydraulic, i-CAD 3D yoyilo, ukusebenza kakuhle kunye nokugcinwa kwamandla okubonakalayo

• Ubunzulu obukhulu besanti, ukuxinana okuphezulu kwe-sureding duud, impompo elungileyo i-NPSH kunye ne-Cruction eQinisekayo.

• Uqinile ngaphakathi-ukubeka, impompo yediliya inokutshintsha igravel, iplastikhi yeplastiki ephezulu, njl.njl.

Isicelo ngokubanzi, impompo yentlabathi inokusetyenziswa kwiindidi ezahlukeneyo zomhlaba.

• Impompo ye-g ye-GANT inokuhambelana ngqo nenjini yombane okanye injini yedizili.

• Impompo ye-g ye-GAPM i-imputha i-3 okanye i-5 iivanes zamasuntswana amakhulu ahambisayo.

• Ilahleko encinci ye-hydradulic, ukusebenza kakuhle kunye nokusetyenziswa kweoyile ephantsi.

• Ukusebenza okungagungqiyo, ukuntywila okuncinci, ingxolo ephantsi.

• Ulwakhiwo olulula noluthembekileyo, ngokulula

• Ukutywinwa okuthembekileyo ngaphandle kokuvuza.

• Ubomi obude bokunxiba.

I-12 / 10g-tg gravel pump yeparamitha

| Imodeli | UMax. Amandla p (kW) | Umthamo Q (M3 / h) | Intloko h (m) | Isantya n (r / min) | I-EFF. η (%) | I-NPS (m) | I-Impholler dia. (mm) |

| I-12x10G-tg | I-600 | I-360-1440 | I-10-60 | I-400-850 | 65 | 1.5-4.5 | 667 |

I-12x10G-TG Dreding Pop Pump Shaft Seal

• Ukupakisha itywina yitywina eliqhelekileyo leShaft.it kusebenza kwiimeko ezahlukeneyo zokumpompa, izixhobo ze-PTF kunye negrafu zokupakisha zinokusetyenziswa kwi-subries ephezulu okanye iimeko zobuso be-cerasic shaft, kwiimeko ze-cesion, i-cerasic shaft iyafumaneka.

• Itywina lomthengisi yi-typer ngamandla e-Impholler ye-Cebirifugal iguqulweyo, ukuthintela ukuvuza. Itywina lomthengisi lingasetyenziswa kwimpompo yenqanaba elinye xa uxinzelelo olufanelekileyo lwe-Inlet alusekho ngaphezulu kwe-10% yoxinzelelo lwe-pump oflet okanye kwi-pump yokuqala kwiPump yoluhlu lwePump.

• Itywina lomatshini liyindlela yokuyila ngaphandle kokutywina ukuvuza, ukudibanisa ulwakhiwo, ufakelo olululo & nokutshintshwa, isuti eyahlukeneyo, iindidi zazo zonke iintlobo zeemeko.

I-12 / 10G-tgImpompo yeGravelIzicelo

• Oweyam: Impompo ye-ore ye-ore ye-ore ye-or

I-metallggy: ukuthutha isilayidi esahlukeneyo se-aluminium okanye ukuvelisa intsimbi.

• Amalahle: Imigodi yamalahle, ukuhlamba kunye ne-Coardes eyahlukeneyo kunye neTlula lokuThuthwa.

• Umbane: Susa i-Ash Shrest Ash, Hlamba i-Ash, i-Ash Ash Desgers okanye i-Ash Slurry Ithuthuthu.

Izixhobo zokwakha: I-Mud ye-Mud yoMdaka

• Imichiza: I-Phosphetiilizer okanye isichumisi se-phossicilic okanye i-potasicic ichumisi

• Ulondolozo lwamanzi: Ichibi, i-daredge, i-sediment, igrit, iplastiki ephakamileyo yeplastiki yokuhambisa.

Phawula:

I-12 × 10 g-tg impompo kunye neendawo eziguquguqukayo zitshintshile nge-Warman® 12 × 10 GG Gumps kunye neendawo zokugcina.

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |