I-1.5 / 1B-i-temube yerabha yerabha ye-pumpry ephezulu

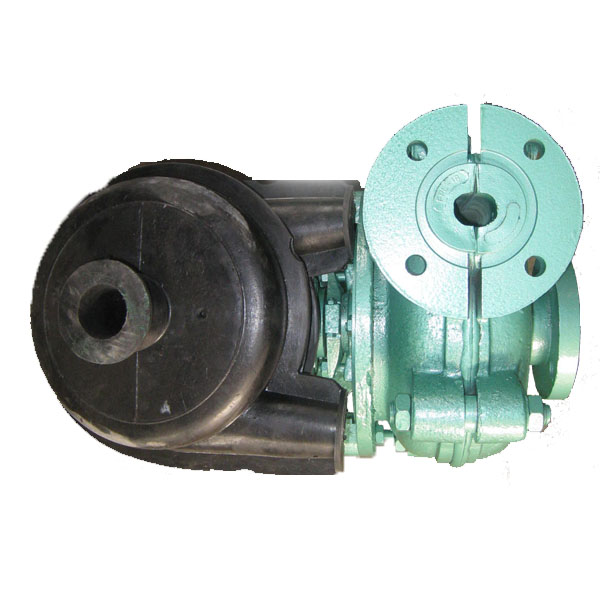

I-1.5 / 1B-i-turber ye-rabber yerabhaNgumsebenzi onzima osemgangathweni olwenziwe ngerabha yerabha.it ifanelekile ekuhanjisweni kwezinto ezincinci okanye i-pumpling kunye ne-pumpling ye-paurber evaliweyo, i-Screusing kunye nokuBuyiselwa kweSountic, i-Minerals yokufumana kwakhona kunye nenkqubo yemichiza yesityalo.

Iimpawu zoyilo:

√cantilever, i-cerricial cerrifugal yerabha ichaphazele impompo ye-slickry

Ukuchasana nesiphelo se-√wet kunye nokuchasana nokuchasana nerabha yerabha

Uxinzelelo lokusebenzela olufanelekileyo yi-3.6MPA.

Itywina le-√experler, itywina lomatshini kunye netywina lokupakisha ziyafumaneka.

I-Ection Crehajet ingabakwenzeka kwixesha le-45 degrees ngesicelo kwaye lijolise kuzo naziphi na izithuba ezisibhozo zokufaka ufakelo kunye nokusetyenziswa.

I-徽标 Guqula ukudlulisela i-abrasion enzima, i-Dredge ephezulu ye-Dredge, umzimba wempompo wempompo usetyenziswa kabini, ngamanye amagama, okwenziwa ngaphaya kwe-lining ngaphakathi nangaphandle kwendawo yokucoca.

1.5 / 1 B i-ter typer impompo yempompo yempompo yempompo yempompo:

| Imodeli | UMax. Amandla (kW) | Izixhobo | Ukucoca amanzi | Umthengisi I-vaney. | |||||

| Liner | Umthengisi | Umthamo Q (M3 / h) | Intloko h (m) | Isantya n (i-RPM) | I-EFF. η (%) | I-NPS (m) | |||

| 1.5 / 1b-Ahr | 15 | Irabha | Irabha | 10.8-25.2 | 7-52 | I-1400-3400 | 35 | 2-4 | 3 |

I-rubber i-pumpry ye-pumpry phumela tywina:

Ukupakisha itywina

Njengomnye wetywina eliqhelekileyo eliqhelekileyo lokujikeleza, ukupakisha itywina elisebenzisa amanzi amdaka, okanye i-teflon okanye i-teflon okanye i-teflon okanye i-aramid fir isetyenziswa njengeemeko zokupakisha i-gland .cing biions eziphezulu, a I-Ceramic Shaft Deftve ifumaneka.

I-centrifugal itywina

Ukudityaniswa komntu oxhasayo kwaye umthengisi wenza uxinzelelo olufunekayo ekutywinelweni. Ndigcwele itywina elisezantsi, okanye ukuba amanzi etywina avumelekile ukuba angene ngaphakathi kwegumbi lokupeyitha.

Itywina lomatshini

I-thring hardery pumpry isebenzisa itywina letywina leTywili elivumela ukufakelwa ngokulula kunye nokutshintshwa.Iintlobo zeTywina loMatshini zizonke izicelo zokwenza impompo ye-slipry yezicelo ezahlukeneyo zempompo.

Sikwasebenzisa i-ceramic ekhethekileyo kunye ne-ALTES yamandla aphezulu kunye nobunzima kumalungu aphantsi kolwazelelelo.

I-Rubber Lien Pumpry Pumpry Pumpry Pumpry Pumps zePumpry:

Ukulungiswa kwemigodi kunye nokulungiswa kwezimbiwa

Isantya esihamba kancinci se-Tobee Hall ye-Tobee Hubber Linder Pump ipompoys, kunye nokukhetha okuxhaphakileyo kwe-Alosion kunye nerabha, ukubonelela ngobomi benkonzo kunye nemilenze yokuqhubela imigodi.

Inkqubo yekhemikhali

Ukutshitshiswa kwezinto kunye necandelo lerabha kwi-pump efanayo, kunye noluhlu olubanzi lwamatywina oomatshini, yenza i-Tobee Home yerabha yerabha ye-slickry yendawo eguqukayo kwimo yomasipala.

Isanti kunye negrabile

Yenzelwe ukuba ibe lula kwaye ilula phantsi kwaye iphinde isebenze kwakhona, i-Tobee Homes ye-Tobee irabha inciphile ixesha lokuphumla linciphisa ixesha lokuphumla, lenza ukhetho olufanelekileyo lokuma ngeempompo.

Ukulungiswa kweswekile

Ukuthembeka kwe-Premiyamu kunye nenkonzo yenkonzo ye-Tobee ye-Tobee Horber i-Tourber Linder Pump icaciswe ziinjineli ezininzi zeswekile zichazwe yimpompo ye-pump ye-pump ngexesha lemfuno ebaluleke kakhulu.

I-Fluel yegesi

Isizukulwana esitsha sokuqhutywa ngokukhethekileyo i-abrasion kunye ne-Alrosion Altss, kunye neTekhnoloji yerabha yakutshanje, izikhundla ze-tobee ziqinile njengomboneleli ophambili kwi-PGD kwishishini le-FGD.

Ukuhlolwa kweoyile kunye negesi

Kwiminyaka eliqela kakhulu siye saqulunqa uyilo olungqiniweyo lwe-tobee ye-tobee irabha i-pumpry pumps pumps pumps ukuba ilungele iimfuno ze-Offshore.

Izicelo zeMizi-mveliso

Naphi na apho inyibilikisi ye-dusile ibangela ukungasebenzi kwangaphambili kweempompo, i-tobee enesidima serabha i-pumpry yempompo inemigangatho yentsebenzo, nxiba ubomi kunye nokuthembeka ukuzisa abathengi ngeyona nto iphantsi yobunini.

Phawula:

I-1.5 / 1 B impompo yerabha yerabha yerabha kunye neenxalenye zitshintshile nge-Warman®1.5 / 1 Ahr Rumpber Linders Pumpry Pumpry Pumps kunye neenxalenye.

Th cantred, ethe tyaba, i-centrifugal impompo yepompo:

| Ikhowudi yezinto | Inkcazo Yezinto Ezibonakalayo | Izinto zesicelo |

| A05 | I-23% -30% ye-cr emhlophe emhlophe | I-Impleller, ii-line, umphandi, i-ring, ibhokisi yokufaka, i-ratatbush, iplate yeplastiki yeplate |

| A07 | I-14% -18% cr emhlophe emhlophe | I-impeller, ii-liners |

| A49 | I-27% -29% cr i-crbon yentsimbi emhlophe | I-impeller, ii-liners |

| A33 | Iipesenti ezingama-33 ze-cr kunye nokuchasana ne-corrosion | I-impeller, ii-liners |

| I-R55 | Irabha yendalo | I-impeller, ii-liners |

| R33 | Irabha yendalo | I-impeller, ii-liners |

| R26 | Irabha yendalo | I-impeller, ii-liners |

| I-R08 | Irabha yendalo | I-impeller, ii-liners |

| U01 | I-polyurethane | I-impeller, ii-liners |

| G01 | Intsimbi engwevu | Iplate yefreyithe, iplate yesakhelo, umthengisi, umsesane we-ring, ethwele indlu, isiseko |

| D21 | I-ductile yentsimbi | Iplate yefreyithe, iplate yesakhelo, indlu ethwele, isiseko |

| E05 | I-carbon yensimbi | Ishafti |

| C21 | Intsimbi engenasitali, i-4ccr13 | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C22 | Intsimbi engenasitayile, i-304ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| C23 | Intsimbi engenasimo, i-316ss | I-Shaft Deleve, i-Lanten Taing, i-Lanter Tottor, iRing, Gland Bolt |

| S21 | I-Butyl Ruber | Amakhonkco adibeneyo, amatywina adibeneyo |

| S01 | Irabha ye-EPDM | Amakhonkco adibeneyo, amatywina adibeneyo |

| S10 | Indrile | Amakhonkco adibeneyo, amatywina adibeneyo |

| S31 | Hypalon | I-Implerler, ii-liners, iringi ekhutheleyo, umphandi, amakhonkco adibeneyo, amatywina adibeneyo |

| I-S44 / k S42 | I-neoprene | I-Impleller, ii-liners, amakhonkco adibeneyo, amatywina adibeneyo |

| S50 | Viton | Amakhonkco adibeneyo, amatywina adibeneyo |